Equipment & Technology

Introduction

Each day, Adam Kasprzak Surveying Ltd. relies on the reliable operation of sophisticated equipment and software to conduct cadastral surveys with precision, efficiency and repeatability. To provide an inside look, below is an overview of the core tools we use, and how they benefit our clients. We are proud to rely on a mix of tried and true equipment and the latest in spatial technologies.

Field Instruments & Tools

Robotic Total Station

We use robotic total stations to measure angles and distances with high accuracy. These instruments allow automatic tracking of a prism, making single-operator setups feasible. This reduces manpower requirements and improves efficiency.

Leica TS12P pictured, acquired in 2019. Learn more Here.

GNSS / RTK Receivers

Our GNSS (Global Navigation Satellite System) receivers support multiple satellite constellations, multiple frequencies, and intelligent operation in real time using RTK (Real Time Kinematic) corrections. GNSS receivers are often the workhorse that measure centimeter-level coordinates across large or remote sites.

Sokkia GRX3 pictured, acquired in 2020. Learn more Here.

Digital Levels

Digital levels are used for elevation measurements and leveling tasks. They interpret coded staff readings (e.g. barcode staffs) to reduce human error and streamline calculations in the field.

Leica Sprinter Digital Level pictured, acquired in 2019. Learn more Here.

Tripods, Poles & Prisms

Stable support is essential for measurement precision. We use rugged and stable tripods, bipods, and range poles. Prisms (reflective targets), tribrachs and other precision hardware are used with total stations and GNSS base/rover setups to capture reliable readings.

Drones & Aerial Survey Platforms

For larger areas or sites with complex geometry, we deploy drones equipped with high-resolution full-frame photographic sensors, and LiDAR sensors. These tools, together with in=house processing software and powerful computation, enable the preparation of digital terrain models, topographic maps, and volume measurements, significantly reducing on-site-time.

Pictured is the DJI M400, acquired in 2025, replacing our previous generation, the M200 and M300. Learn more at https://enterprise.dji.com/matrice-400

LIDAR sensor

LiDAR works by sending out rapid laser pulses and measuring how long it takes for each pulse to bounce back from a surface — the time gives distance, and combining millions of these measurements creates a precise 3D map of the environment.

The DJI Zenmuse L2 is a compact aerial LiDAR payload that combines a laser scanner, a high-precision IMU, and a 20 MP RGB camera to capture detailed 3D point clouds and imagery with centimetre-level accuracy.

Learn more at https://enterprise.dji.com/zenmuse-l2

Metal Detector

The Schonstedt GA-52Cx (used by our firm for over 25 years) is a magnetic locator that detects disturbances in the Earth’s magnetic field caused by ferrous (iron/steel) objects, using sensitive magnetic sensors; when you move it over underground metal, it senses the local magnetic gradient and converts that into an audible and/or visual signal. Used as the fundamental instrument for exposing the locations of buried survey monuments.

Learn more at https://www.schonstedt.com/products/ga-52cx/

Rock Drill

Gasoline-powered rotary hammer drills that uses a piston and crank mechanism plus a hammering action to deliver high impact energy, drill or chisel through concrete, masonry or rock. We use these (and the modern lithium powered SDS drills) to set iron bars (survey monuments) at locations where bedrock, concrete, etc. presents technical challenges.

Pictured is the Ryobi ER-382, which we have several.

Utility Task Vehicle (UTV)

The Kubota RTV1100 is a rugged utility terrain vehicle (UTV) powered by a 3-cylinder diesel engine (~24.8 hp), with hydrostatic (stepless) transmission, 4-wheel drive, and a cargo bed — designed for off-road hauling, towing, and worksite tasks.

Enabling fieldcrew and equipment to access remote backcountry enables us to conduct surveys in an efficient and effective manner.

Acquired in 2020

ARGO Centaur

The ARGO Centaur is a rugged eight-wheel drive amphibious utility vehicle. Its power comes from a liquid-cooled, 3-cylinder turbo-diesel engine (≈ 958 cc, ~34 hp, 58 lb-ft torque in older versions) which drives the wheels via a dual-differential hydrostatic transmission. This vehicle can carry a payload of about 2,000 lb.

The ARGO Centaur is exceptionally capable in winter, using its eight-wheel-drive system, sealed axles, and optional track kits to traverse deep snow, ice, and frozen terrain with ease. Its low ground pressure and enclosed heated cab make it ideal for reaching remote, otherwise inaccessible locations in winter conditions.

Acquired in 2024

Software & Data Processing

Drafting Software

To calculate boundaries, draft plans and survey deliverables, and compute spatial data, we use the well-established computer aided design (CAD) software known as MicroSurvey EmbeddedCAD 2025, built using the AutoCAD IntelliCAD Engine. Microsurvey’s purpose-built software has been used by our firm for over 20 years.

This program, built on AutoCAD’s platform, is the industry standard, compatible with all other licensed autocad variations. is a standalone survey-oriented CAD software that combines drafting, surveying calculations, and “field-to-finish” tools — it supports DWG natively, handles COGO, traverse adjustments, surface modeling, point-cloud import/export, and works with popular data collectors. We produce .dwg files which can be integrated into workflows by Architects, Engineers and Planners.

3DSurvey (Photogrammetry Software)

Photogrammetry is based on the simple geometric idea of triangulation — the same concept our eyes use for depth perception. When two or more overlapping photographs capture the same feature from different angles, the software can mathematically compute that feature’s position in 3D space.

To do this, 3Dsurvey uses a process called Structure-from-Motion (SfM). It detects thousands of common visual points (like rocks, corners, or painted markers) across many images. Each point’s location on the photo is known in pixel coordinates, and by analyzing how that point shifts between images, the software estimates both the camera’s position and orientation and the 3D location of the point. Once camera geometry is solved, 3Dsurvey applies multi-view stereo (MVS) algorithms to fill in surface details between those matched feature points. This creates a dense 3D point cloud, containing millions of precisely calculated coordinates representing the landscape or object surface.

Then, using ground control points (GCPs) or RTK GNSS metadata from drones, 3Dsurvey aligns the model into real-world coordinates — turning the relative 3D model into a georeferenced one accurate to within centimeters. From this point cloud, the software automatically generates orthophotos, contours, digital terrain models (DTM/DSM), and volume reports - true-to-scale, measurable surfaces suitable for engineering design, construction monitoring, and many other applications

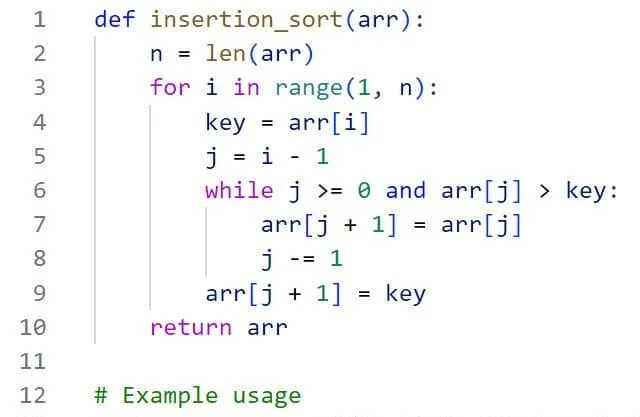

Python PDF Sorting Algorithm

We curate the only collection of survey records of Renfrew County, some of which date back as far as the mid 1800s. To organize the huge collection of paper and vellum survey records, our focus was to develop a digital catalog that was intuitive for our Team to conduct research answering the fundamental question in this business: “Is there a survey plan on or nearby my parcel?”

A folder structure was developed inhouse based on the unique cadastre of Renfrew County. Sorting the records manually into the folder structure would be an inefficient use of time over the long-term. We chose to innovate and use the power of AI to aid the development of a ‘Customized Sorting Algorithm’.

Our custom python software, developed in-house, uses Optical Character Recognition (OCR) software (computer vision) and pattern recognition to “read” printed or handwritten text from images or PDFs, converting it into searchable and editable digital text.

This custom-developed OCR technology scans a PDF image of each survey plan to identify key pieces of information — such as lots and concession details — using algorithms trained to recognize letter shapes and spatial patterns. The extracted text is then analyzed using rule-based logic or natural language processing to classify and route the document to the correct folder in our growing server library.